Hello there, budding plumber! If you’re looking to dive into the world of DIY plumbing, specifically working with PEX tubing, you’ve come to the right place. Cutting PEX pipe might seem daunting, but with the right tools and techniques, it’s a breeze. Let’s embark on this plumbing journey together, shall we?

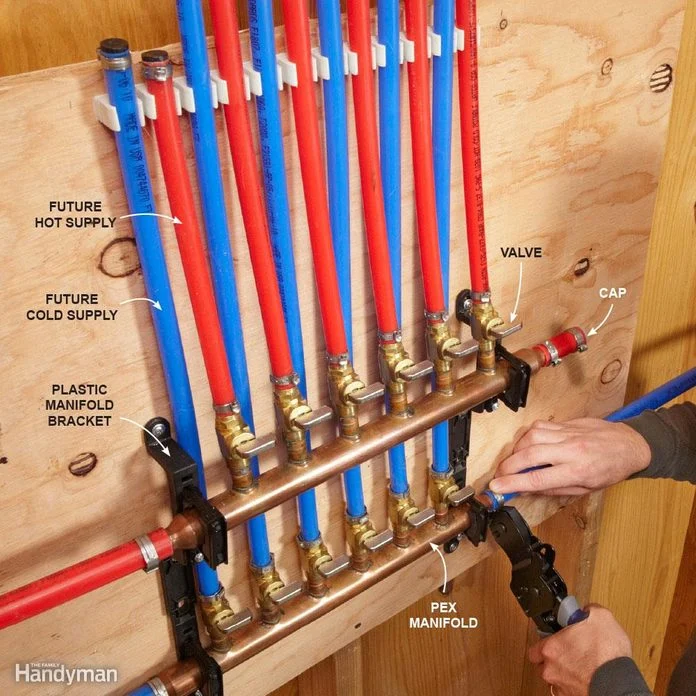

Brief Overview of PEX Pipes and Their Advantages in Plumbing

PEX, or cross-linked polyethylene, has revolutionized the plumbing industry. Introduced in Europe in the 1960s and the U.S. in the 1980s, PEX tubing offers several advantages over traditional plumbing materials like copper pipes and PVC pipes. It’s flexible, resistant to both leaking pipes and corroded pipes, and can withstand extreme temperatures, making it ideal for a variety of plumbing applications.

Importance of Making a Clean Cut for Effective Plumbing Connections

In plumbing, precision is key. A clean cut ensures that your connections are secure, reducing the risk of leaks and ensuring the longevity of your plumbing systems. Whether you’re using a pipe cutter, ratchet cutter, or even a utility knife, always measure twice and cut once.

Understanding PEX Tubing

Dive deeper into the world of PEX and discover its origins, composition, and the differences between its types.

Origin and Composition of PEX

PEX stands for cross-linked polyethylene. It’s made by linking the polymer chains of polyethylene, resulting in a more durable material. This cross-linking process provides PEX with its unique flexibility and resistance to high temperatures, making it a favorite in modern plumbing solutions.

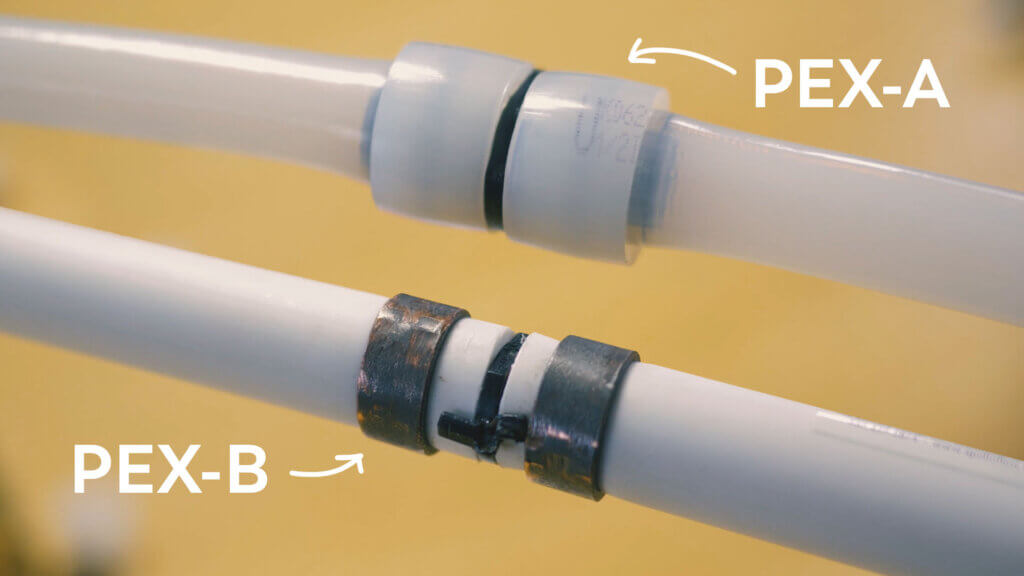

Differentiating Between PEX-A, PEX-B, and PEX-C

There are three main types of PEX tubing, each produced using a different method:

- PEX-A: Produced using the Engel method, PEX-A is the most flexible of the three and has the highest degree of cross-linking. It’s ideal for applications requiring tight bends.

- PEX-B: Made using the Silane method, PEX-B is slightly less flexible than PEX-A but is still more flexible than traditional plumbing materials. It’s the most commonly used type in the U.S.

- PEX-C: Produced using the Electron Beam method, PEX-C is the least flexible of the three but offers excellent high-temperature resistance.

Essential Tools for Cutting PEX

Before we dive into the actual cutting process, it’s crucial to have the right tools on hand. The right tool can make your job easier, safer, and more precise. Here’s what you’ll need:

PEX Tubing Cutters

These are specialized cutting tools designed specifically for PEX tubing. They ensure a clean, straight cut, which is essential for preventing leaks and ensuring a secure fit with fittings like the popular SharkBite or JACO. When it comes to plumbing tools, investing in a good PEX cutter is a wise decision.

Scissors or Utility Knife (not recommended for precise cuts)

While a utility knife or scissors can be used in a pinch, they aren’t ideal for precise cuts. They might leave you with ragged edges or an uneven cut, which can lead to plumbing issues down the line.

Ratchet-Style Cutters for Larger Diameters

For those larger PEX pipes or when dealing with plumbing systems that require bigger diameters, a ratchet-style cutter is your best friend. It provides the leverage and precision needed for those heftier jobs.

Step-by-Step Guide to Cutting PEX Pipe

Alright, now that you’ve got your tools ready, let’s get down to the nitty-gritty of cutting that PEX tubing.

Marking the Desired Length

- Lay out your PEX tubing on a flat surface.

- Using a measuring tape, determine the length you need.

- Mark the spot with a non-permanent marker. This ensures you get the exact length required for your plumbing project.

Ensuring a Straight Cut

- Hold the PEX tubing firmly with one hand.

- With your chosen cutting tool, position the blade at the marked spot.

- Apply steady pressure and make a straight cut. Remember, a straight cut is crucial for preventing leaking pipes and ensuring a snug fit with your fittings.

Tips to Avoid Burrs or Ragged Edges

- Always use sharp cutting tools. Dull tools can lead to ragged edges.

- After cutting, inspect the end of the PEX tubing. If you notice any burrs, use a deburring tool or fine-grit sandpaper to smooth them out.

- Avoid using a utility knife or scissors for precise cuts. As mentioned earlier, they can lead to less-than-perfect results.

Safety Precautions

Safety first! Before you even think about making that first cut, let’s ensure you’re taking the necessary precautions.

Wearing Gloves to Prevent Cuts

PEX tubing might seem soft, but a slip of the hand can lead to nasty cuts. Always wear gloves, preferably made of a durable material, to protect your hands. Not only will they shield you from potential injuries, but they’ll also give you a better grip on your plumbing tools and materials.

Keeping the Cutting Tools Sharp for Clean Cuts

A dull pipe cutter or utility knife can lead to jagged edges, which can cause leaking pipes down the line. Regularly sharpen your tools or invest in high-quality cutting tools that retain their edge. Remember, in the world of plumbing, precision is key.

Connecting PEX to Other Materials

PEX is versatile, but chances are, you’ll need to connect it to other types of pipes in your plumbing system. Here’s how:

Joining PEX to Copper Using Male Sweat Adapters

Copper pipes have been a staple in plumbing for years. To connect PEX tubing to copper:

- Slide a copper crimp ring onto the PEX tubing.

- Push the tubing onto the copper pipe until it touches the shoulder of the fitting.

- Use a crimping tool to secure the connection. Ensure you’re following plumbing codes and standards for a secure fit.

Connecting PEX to CPVC with Cinch Clamps

CPVC pipes are commonly used in home plumbing systems. To connect PEX to CPVC:

- Slide a cinch clamp onto the PEX tubing.

- Insert the CPVC pipe into the PEX tubing.

- Use a ratchet cutter to secure the cinch clamp, ensuring a tight and leak-free connection.

Using Transitional Fittings for Dissimilar Pipes

Sometimes, you’ll encounter a mix of galvanized steel pipes, PVC pipes, or even corroded or rusty pipes. Transitional fittings, like the SharkBite or JACO fitting, are your best friends here. They allow for a seamless connection between PEX and other materials, ensuring your plumbing system remains robust and leak-free.

Expert Tips from Plumbers

Every trade has its secrets, and plumbing is no exception. Here are some golden nuggets of wisdom from seasoned plumbers:

Importance of Using Manufacturer-Approved Connectors

While it might be tempting to use any connector you find, it’s crucial to use those approved by the PEX tubing manufacturer. These connectors are tested for optimal performance with the tubing, ensuring a leak-free connection and longevity. Remember, a plumbing system is only as strong as its weakest link.

Avoiding Proprietary Connectors for Flexibility

Proprietary connectors can lock you into a specific brand, limiting your flexibility in future plumbing repairs or upgrades. Opt for universal connectors like the SharkBite fitting or JACO fitting, which offer compatibility with various PEX tubing brands and other materials like copper pipes or PVC pipes.

Ensuring the Outside Portion of the Pipe is Free of Burrs and Scratches Before Connecting

A smooth pipe exterior is crucial for a secure connection. Before connecting, inspect the PEX tubing for any burrs or scratches. If present, use a deburring tool or fine-grit sandpaper to smooth out the imperfections. This simple step can prevent potential plumbing issues down the line.

Common Mistakes to Avoid

Even seasoned plumbers can make mistakes, but being aware of them can save you time, money, and potential plumbing emergencies.

Not Marking the Pipe Before Cutting

Always mark the desired length on your PEX tubing using a measuring tape and a non-permanent marker. This ensures precision and avoids wastage.

Using the Wrong Cutting Tool

While a utility knife might be handy, it’s not ideal for PEX. Invest in a dedicated pipe cutter or ratchet cutter for clean, straight cuts. Your plumbing system will thank you for it.

Not Ensuring a Straight Cut

A skewed cut can lead to leaking pipes and a weak connection. Always ensure your cuts are straight. If in doubt, use a square or straight edge as a guide.

Benefits of Using PEX Over Traditional Pipes

PEX tubing has revolutionized the plumbing industry, and for good reasons. Here’s why many professionals and DIY enthusiasts alike are making the switch:

Flexibility and Ease of Installation

PEX tubing is incredibly flexible, allowing it to bend around corners without the need for elbow fittings. This flexibility reduces the number of connections, decreasing the potential for leaks. According to a study by the Plastic Pipe Institute, PEX’s flexibility can reduce installation time by up to 60% compared to copper or PVC pipes.

Resistance to Corrosion and Scaling

Unlike copper pipes, which can corrode over time, especially in areas with acidic water, PEX tubing is resistant to corrosion. It’s also resistant to mineral buildup, ensuring a steady flow rate and reducing the risk of clogs. This means fewer plumbing repairs and a longer lifespan for your plumbing system.

Cost-Effectiveness

PEX tubing is generally more affordable than copper or galvanized steel pipes. Additionally, because it requires fewer fittings and has a quicker installation time, labor costs are often reduced. This makes PEX an excellent choice for those looking for plumbing solutions that offer both quality and value.

Conclusion

Recap of the Importance of a Clean Cut

As we’ve journeyed through the world of PEX, one thing remains clear: the importance of a clean, straight cut. It’s the foundation of a leak-free connection and a robust plumbing system. Always mark your PEX tubing with a measuring tape, use a sharp pipe cutter or ratchet cutter, and ensure the cut is straight.

Encouraging Readers to Invest in the Right Tools and Techniques for Optimal Results

Your plumbing project’s success hinges on the tools and techniques you employ. Investing in high-quality plumbing tools and supplies, like the SharkBite fitting or JACO fitting, can make all the difference. Remember, in the realm of DIY home improvement, knowledge is power. Equip yourself with the latest plumbing insights, stay updated with plumbing trends, and always prioritize safety and precision.