What are Polybutylene Pipes?

Polybutylene pipes are a type of plastic piping used in residential and commercial plumbing systems. They were popular from the 1970s to the mid-1990s due to their low cost, flexibility, and ease of installation. These pipes are usually gray, blue, or black and were commonly used for both water supply lines and sewage systems.

History and Use of Polybutylene Pipes

Polybutylene pipes gained popularity in the United States and Canada in the 1970s as a cost-effective alternative to traditional copper and galvanized steel pipes. They were extensively used in new construction and plumbing system upgrades. However, by the mid-1990s, it became evident that polybutylene pipes were prone to degradation and failure, leading to their discontinuation in the late 1990s.

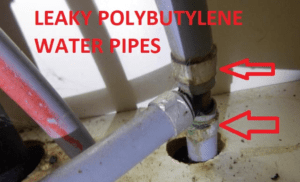

Problems with Polybutylene Pipes

The primary issue with polybutylene pipes is their tendency to become brittle and crack over time. The degradation process can be accelerated by exposure to chlorine and other chemicals commonly found in municipal water supplies. As the polybutylene pipes deteriorate and weaken, they become susceptible to leaks and bursts, leading to water damage, mold growth, and costly repairs for homeowners.

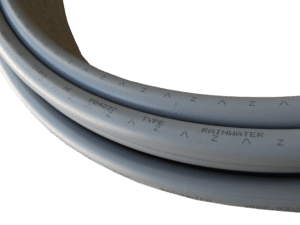

Identifying Polybutylene Pipes in Your Home

To determine if your home has polybutylene pipes, check the color and markings on your plumbing system. Polybutylene pipes are typically gray, blue, or black and may have “PB” or “PB2110” printed on them. They are often found in the water supply lines and can be visible in your home’s basement, crawl space, or utility room. You may also find them connecting to your water heater, plumbing fixtures, or main shut-off valve. If you are unsure whether you have polybutylene pipes, consider hiring a licensed plumber to inspect your plumbing system.

Factors that Affect the Cost of Replacing Polybutylene Pipes

Size and Complexity of Your Plumbing System

The overall cost of replacing polybutylene pipes will depend on the size and complexity of your plumbing system. Larger homes with multiple bathrooms and more fixtures will require more materials and labor, increasing the overall cost. The layout of your plumbing system can also impact the price, as complex systems with numerous bends and turns may require additional time and effort to replace.

Location of Your Pipes

The accessibility of your polybutylene pipes will influence the replacement cost. If pipes are located in hard-to-reach areas such as crawl spaces, behind walls, or under concrete slabs, additional labor and equipment may be needed, resulting in higher costs.

Type of Replacement Pipes Needed

The type of pipes you choose to replace your polybutylene pipes will also impact the cost. Common replacement options include copper, PEX (cross-linked polyethylene), and CPVC (chlorinated polyvinyl chloride). Each material has its own advantages and drawbacks, with copper generally being the most expensive option and PEX and CPVC pipes being more affordable alternatives. The choice of material will depend on your budget, local building codes, and your contractor’s recommendations based on your specific needs.

How Much Does it Cost to Replace Polybutylene Pipes?

Average Cost of Polybutylene Pipe Replacement

The average cost of replacing polybutylene pipes in a home can range from $2,500 to $15,000 (Source) or more, depending on various factors mentioned earlier. This cost includes materials, labor, and any necessary permits. Keep in mind that every project is unique, and individual costs can vary based on your specific situation.

Factors that Affect the Cost of Replacement

As discussed earlier, factors such as the size and complexity of your plumbing system, the location of your pipes, and the type of replacement pipes needed for re-plumbing will all influence the total cost of replacing polybutylene pipes in your home.

Cost Comparison of Different Replacement Options

When comparing the cost of different pipe materials, copper is typically the most expensive option, with an average cost of $2.50 to $4.50 per linear foot. PEX and CPVC are more affordable alternatives, with PEX costing between $0.50 and $2.00 per linear foot, and CPVC costing between $0.75 and $1.50 per linear foot. Keep in mind that these are just material costs and do not include labor or other associated expenses.

Related Post: how much does it cost to replumb a house

Choosing a Contractor for Polybutylene Pipe Replacement

Tips for Finding a Reputable Contractor

Research and referrals: Start by asking friends, family, or neighbors for referrals. You can also search online for contractors in your area, read customer reviews, and check their ratings on websites like the Better Business Bureau (BBB).

Verify credentials: Make sure the contractor is licensed, bonded, and insured. Check their license status with your state’s licensing board, and request proof of insurance.

Obtain multiple quotes: Get at least three estimates from different contractors to compare their pricing, services, and warranties. This will help you make an informed decision based on quality and value.

Questions to Ask Before Hiring a Contractor

- How long have you been in business, and do you have experience with polybutylene pipe replacement?

- Can you provide references from past clients who had similar projects?

- What type of pipes do you recommend for the replacement, and why?

- How long will the project take, and what is the estimated cost?

- Will you handle obtaining the necessary permits and inspections?

- What kind of warranty do you provide on your work and materials?

What to Expect During the Replacement Process

During the polybutylene pipe replacement process, you can expect:

Preparation: The contractor will prepare the work area by laying down protective coverings and setting up equipment.

Pipe removal: Old polybutylene pipes will be removed and safely disposed of.

Pipe installation: New pipes will be installed, ensuring proper connections and compliance with local building codes.

Testing: The contractor will test the new plumbing and piping system for leaks and proper functionality.

Clean up: The work area will be cleaned up, and any debris or waste materials will be removed.

Final inspection: A final inspection may be conducted by your local building department to ensure the replacement work meets all required codes and standards.

Alternative Options to Replacing Polybutylene Pipes

Pipe Coating and Lining

Pipe coating and lining are methods used to extend the lifespan of existing pipes without complete replacement. This process involves cleaning the interior of the pipes and applying a protective coating or lining material, such as epoxy or cured-in-place pipe (CIPP) liners. While this option can be more cost-effective in the short term, it may not be suitable for severely deteriorated polybutylene pipes.

Pipe Repair and Maintenance

In some cases, small leaks or damage to polybutylene pipes can be repaired rather than replaced. This can involve patching, clamping, or using specialized leak repair fittings. However, this is typically a temporary solution, as the underlying issue with polybutylene pipes remains unresolved and may lead to future leaks or failures.

Whole-Home Repiping

In situations where polybutylene pipes are only part of a larger, outdated plumbing system, whole-home repiping may be the best solution. This involves replacing all the pipes in your home, not just the polybutylene pipes, with a modern, durable material like PEX, CPVC, or copper. While this option can be more expensive, it can provide long-term benefits by improving the overall performance and reliability of your plumbing system, increasing your home’s value, and reducing the risk of future leaks and water damage.

FAQ

What is the cost of replacing polybutylene pipes?

The cost of replacing polybutylene pipes can range from $4,000 to $15,000 or more, depending on factors such as the size and complexity of your plumbing system, the location of your pipes, and the type of replacement pipes needed.

How do I know if I have polybutylene pipes in my home?

Polybutylene pipes are typically gray, blue, or black and may have “PB” or “PB2110” printed on them. They can be found in your home’s basement, crawl space, or utility room, and are often connected to your water heater, fixtures, or main shut-off valve.

Can I replace polybutylene pipes myself?

Replacing polybutylene pipes is a complex and labor-intensive process that requires specialized knowledge and skills. It is highly recommended to hire a licensed and experienced plumber to ensure the polybutylene piping job is done correctly and safely and in compliance with local building codes.

What are the risks of not replacing polybutylene pipes?

Failing to replace polybutylene pipes can lead to leaks, bursts, water damage, mold growth, and costly repairs. These pipes are prone to degradation and failure, making it essential to replace them to avoid potential risks to your home and your family’s safety.

How long does it take to replace polybutylene pipes?

The duration of a polybutylene pipe replacement project can vary depending on factors such as the size and complexity of your plumbing system and the accessibility of the pipes. On average, a pipe replacement project can take anywhere from a few days to a couple of weeks.

Conclusion

Replacing polybutylene pipes is an important investment to protect your home from potential water damage, mold growth, and costly repairs. By understanding the factors that affect the cost of replacement, exploring different pipe materials, and selecting a reputable contractor, you can ensure that your home’s plumbing system remains safe, functional, and up to code. While the cost of replacing polybutylene pipes may seem significant, the long-term benefits of a reliable and efficient plumbing system will provide peace of mind and protect the value of your property.